7 expert-approved design tips for T-Shirt Printing that convert

Wiki Article

From Design to Shipment: Grasping the Art of T-Shirt Screen Printing

The trip from style to delivery in t-shirt screen printing incorporates a collection of critical phases that demand focus to detail and critical preparation. It starts with understanding the subtleties of your target audience, followed by the choice of proper products and the prep work of art work that fulfills high standards. Yet, as the process unravels, challenges in quality control and logistics can occur, potentially impacting the final result. Exploring these complexities reveals not just the intricacies of screen printing however additionally the essential practices that can boost a brand name's standing in a competitive market.Comprehending T-Shirt Screen Printing

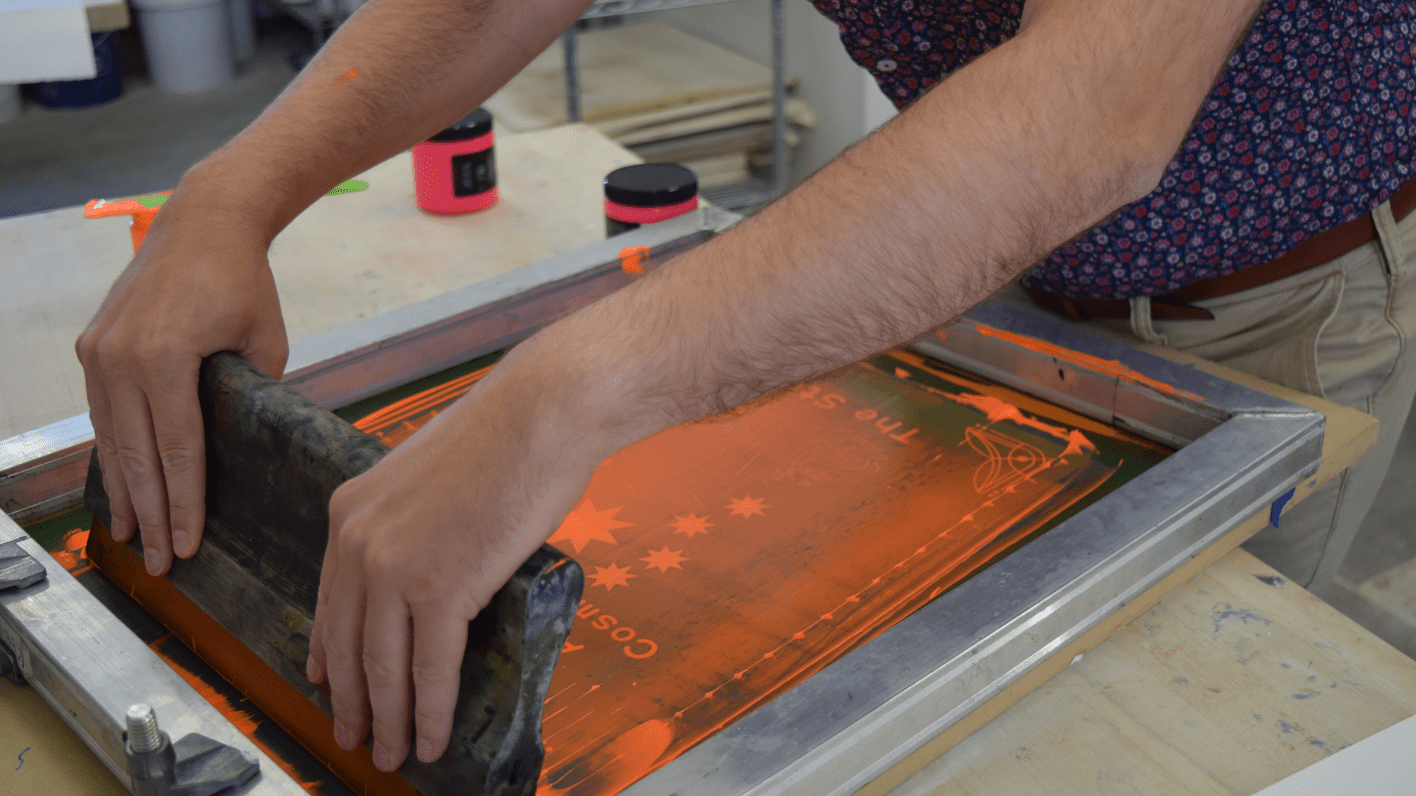

Comprehending T-Shirt screen printing includes identifying a versatile and commonly utilized method for moving styles onto material. This method utilizes a pattern and a mesh screen to apply ink onto various fabric products, primarily cotton and polyester blends. The process starts with the production of a screen that features the wanted style, which is after that carefully lined up on the material.Ink is pushed through the screen's open locations utilizing a squeegee, enabling precise application of shade. This approach is favored for its ability to create dynamic, long-lasting prints that stand up well to washing and put on. In addition, screen printing is qualified of accommodating both straightforward and complicated styles, making it a recommended option for custom apparel, advertising products, and also artistic works.

Screen printing uses scalability, making it suitable for both little set orders and large-scale manufacturings. While initial configuration prices may be greater compared to various other printing techniques, the performance and longevity of screen printing frequently justify the investment. Generally, recognizing the basics of Tees screen printing is essential for anyone seeking to take part in this prominent form of fabric design, whether for commercial endeavors or personal tasks.

Conceptualizing Your Style

Conceptualizing your style is a vital step in the Tee shirts screen printing procedure, as it establishes the structure for the entire job (Screen Printing). This phase involves producing concepts that reverberate with your target market while ensuring that the design aligns with the brand's identification and message. It is necessary to begin by exploring themes, color plans, and graphics that show the designated aestheticMapping out first principles can be valuable, permitting a graph of ideas prior to wrapping up the layout. Take into consideration using typography, images, and format in a means that catches interest and interacts successfully. On top of that, it is vital to expect the printing method that will be employed, as this can influence layout intricacy and color selections.

Taking part in conceptualizing sessions with staff member or seeking comments from potential customers can also boost the concept process, providing varied perspectives that refine the design. Eventually, a well-thought-out style not only boosts the aesthetic allure of the Tee shirts but also fosters a link with the audience, driving interest and possible sales. As a result, devoting time to conceptualize your layout can result in an effective screen printing end result.

Selecting the Right Products

The weight of the material, generally determined in grams per square meter (GSM), affects the drape and general feeling of the Tee shirts. Much heavier materials may offer a more exceptional look, while lighter alternatives are comfy for sportswear. Structure also plays a role; smoother textiles often tend to generate sharper prints, while textured surface areas can create special aesthetic impacts.

Additionally, consider the environmental impact of products. Organic cotton and recycled polyester are obtaining appeal amongst eco-conscious consumers. Eventually, picking the ideal materials includes balancing visual charm, capability, and sustainability, making certain that the Tee shirts not only looks fantastic yet likewise fulfills the assumptions of your target audience.

Preparing Art Work for Printing

Preparing artwork for T-shirt screen printing needs careful interest to detail to guarantee that the last print precisely shows the intended style. The primary step is to develop a high-resolution electronic file, preferably in vector layout, as this enables for scalability without loss of top quality. Typical software utilized for this objective includes Adobe Illustrator and CorelDRAW.Next, validate that all text is transformed to lays out or rasterized to avoid font problems during printing (Abilene T-Shirt Screen Printing Company). In addition, it is vital to confirm that the shade setting is set to CMYK, as this straightens with the printing process. Pay attention to shade matching; utilizing Pantone shades can help accomplish uniformity across different prints

Think about the dimensions of the print area and preserve correct margins to avoid design cutoff. It's additionally wise to include enrollment marks for alignment during the printing process. Business Branding Services. Finally, request an evidence from the printer to envision the last product before mass production. This step is important for recognizing any prospective problems, assuring that the published Tee shirts fulfills the wanted top quality and design specs. Appropriate preparation of art work substantially affects the general success of the screen printing task

Mastering the Printing Process

Mastering the printing procedure is vital for accomplishing top notch lead to Tee shirts screen printing. This phase involves several significant actions that directly influence the end product. The very first step is setting up the printing press accurately. Proper enrollment of screens warranties that shades line up correctly, preventing misprints and assuring a specialist look.

Next, selecting the appropriate ink is essential. Different ink types, such as plastisol or water-based, deal different finishes and resilience. Understanding the textile structure of the T-shirt additionally assists in choosing suitable inks.

When it concerns the actual printing, managing the squeegee pressure and angle is crucial. Consistent stress will produce even ink circulation, while the angle impacts the circulation and protection. In addition, readjusting the speed of the printing machine can impact the ink's healing process, which is basic for ensuring durability.

High Quality Control and Finishing

After the printing procedure is complete, applying efficient top quality control steps ends up being important to confirm that each T-shirt satisfies the wanted standards. Quality assurance involves a methodical approach to examining each garment for issues, confirming that the print high quality, color accuracy, and material honesty straighten with the specifications established throughout the design phase.

The primary step in quality assurance is a detailed aesthetic inspection. This entails checking for usual concerns such as imbalance, ink smudges, or fading. Any T-shirt that does not satisfy the high quality benchmarks ought to be dealt with quickly, either via reprinting or fixing.

Along with aesthetic checks, it is crucial to carry out laundry examinations on a sample of printed shirts to assess the longevity of the inks and the overall long life of the style. These examinations assist validate that the print will certainly preserve its vibrancy and integrity after multiple cleans, an important factor for consumer fulfillment.

Completing touches, such as thread trimming and the application of treatment Continue tags, also play a substantial duty in top quality control - T-Shirt Printing. By focusing on these facets, services can enhance the total discussion of their products, inevitably resulting in an extra satisfying consumer experience

Packaging and Delivery Solutions

To accomplish optimal product packaging, take into consideration using environmentally friendly materials that line up with sustainability patterns, such as recyclable poly bags or naturally degradable boxes. Each Tees must be nicely folded up and put in protective wrapping to avoid creasing and prospective damage during transit. Including a branded insert or care instructions can further individualize the experience, cultivating customer commitment.

Picking a trustworthy shipping companion is essential when it comes to distribution. Examine choices based on rate, expense, and tracking capacities. Offering numerous delivery methods can satisfy various client needs, from basic to expedited delivery.

Frequently Asked Questions

What Are the Typical Blunders Beginners Make in Screen Printing?

Usual mistakes newbies make in screen printing include improper screen prep work, inadequate ink blending, wrong direct exposure times, inadequate healing, and ignoring to test prints. These mistakes can cause low quality and unacceptable lead to final items.Just How Can I Stop Ink From Blood Loss Throughout Printing?

To stop ink bleeding during printing, warranty appropriate screen stress, use appropriate solution density, pick the best ink uniformity, maintain perfect healing temperatures, and prevent straining the screen with excessive ink throughout application.What Types of Inks Are Finest for Various Fabrics?

Selecting inks based on material kind is important. Water-based inks are excellent for cotton, offering gentleness. Plastisol inks match artificial fabrics, supplying sturdiness. Release inks efficiently blend with all-natural fibers, making sure vibrant colors without jeopardizing textile honesty.How Do I Choose the Right Screen Mesh Matter?

Picking the appropriate screen mesh matter depends upon the preferred print information and ink kind. Abilene T-Shirt Printing Solutions. Higher mesh counts produce better details, while lower counts promote thicker inks. Assess fabric kind and design complexity for perfect resultsCan I Utilize Screen Printing for Little Set Orders?

Yes, screen printing can be effectively used for little set orders. This approach allows for comprehensive styles and high-grade outcomes, making it a viable option for customized clothing, marketing things, or minimal version runs.Recognizing T-Shirt screen printing entails recognizing a functional and widely used method for transferring designs onto fabric. While initial setup costs might be greater contrasted to other printing techniques, the effectiveness and toughness of screen printing usually warrant the financial investment. Preparing artwork for T-shirt screen printing requires mindful focus to information to ensure that the final print accurately mirrors the intended layout. Understanding the printing process is important for achieving high-quality outcomes in Tees screen printing. Typical errors beginners make in screen printing consist of incorrect screen preparation, poor ink blending, incorrect direct exposure times, inadequate treating, and neglecting to examine prints.

Report this wiki page